The manufacturing industry in the United States is a vital part of the country’s economy. This sector employs millions of Americans and produces a wide range of products that consumers use worldwide. Several factors have contributed to the success of this industry, including technological innovations, vital infrastructure, and skilled workers.

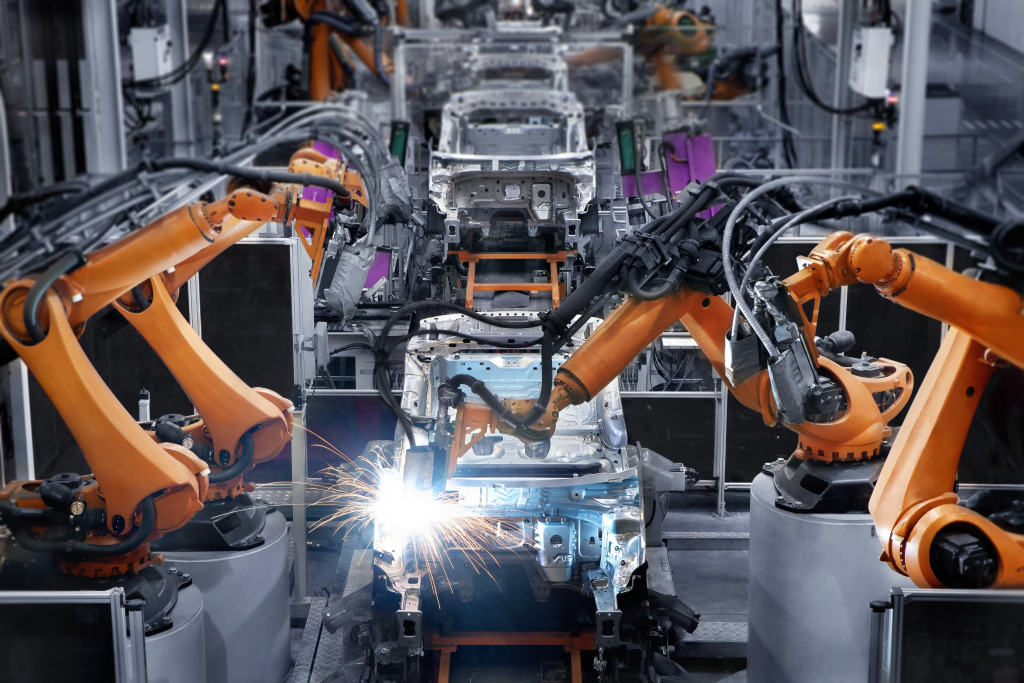

One major factor behind the success of the manufacturing industry in the US has been advances in technology. Over time, machines have become more sophisticated and efficient, allowing manufacturers to produce higher volumes at lower costs. Additionally, automation has reduced labor requirements, which has allowed companies to keep production levels high while controlling costs.

One of the best subsectors in this trillion-dollar industry is direct-to-consumer manufacturing (DTC).

What is Direct-to-Consumer Manufacturing (DTC)?

DTC manufacturing refers to producing goods directly for consumers without going through traditional distribution channels. This approach has become increasingly popular due to advances in technology and logistics.

With DTC, manufacturers can produce small batches of customized products at a much lower cost than traditional methods allow, which has made this model especially appealing to startups and entrepreneurs.

Additionally, DTC manufacturers can more easily compete with established brands on price and quality by cutting out distributors and retailers. Despite these advantages, there are some challenges associated with DTC manufacturing that companies need to be aware of.

For example, it can be challenging to manage inventory levels when production is continuous effectively, and orders are received frequently. However, many businesses find that the benefits of DTC manufacturing far outweigh the challenges and continue to see tremendous growth in this area.

Here are some principles you should follow to succeed.

Use automation to streamline production processes

One of the best ways to improve efficiency and quality in manufacturing is to use automation. You can free up workers to focus on more value-added activities by automating repetitive tasks. Additionally, automation can help to reduce defects and improve consistency.

If you’re starting in DTC manufacturing, choosing the right production processes to automate is essential. You’ll also need to consider the cost of investing in automation equipment carefully. In many cases, the upfront investment will pay for itself over time through increased efficiency and productivity.

Work closely with suppliers

Another critical factor in the success of DTC manufacturing is working closely with suppliers. When you have a good relationship with your suppliers, you’ll be able to get the materials and components you need in a timely manner. This is especially important if you’re starting and don’t have much buffer in terms of inventory.

If there is one supplier, you should always keep in touch with metal suppliers. They play a significant role in your bottom line, and regardless of what you’re manufacturing, you’ll need their steel. So make sure to be in a good relationship with them.

Invest in logistics

Good logistics and fulfillment are essential for any manufacturing business, but they’re critical in DTC manufacturing. Since you’re selling directly to consumers, it’s important to ensure that orders are fulfilled quickly and accurately. This will require a significant investment in logistics and fulfillment infrastructure, but it will be worth it in the long run.

Flexibility and adaptability

In traditional manufacturing, companies often produce large quantities of a single product. This “batch-and-queue” approach is no longer feasible in the world of DTC manufacturing. Instead, manufacturers need to be flexible and adaptable to changing consumer needs.

This requires a different approach to inventory management. Instead of producing large quantities of a single product, manufacturers need to produce smaller batches of multiple products. This “made-to-order” approach allows companies to be more responsive to consumer demand and reduces the risk of excess inventory.

Build strong customer relationships

Perhaps one of the biggest advantages of DTC manufacturing is that you have direct contact with your customers. This direct contact allows you to build relationships and understand their needs, which can help you to improve your products and win repeat business.

To build strong customer relationships, it’s important to focus on providing high-quality customer service. This includes responding quickly to complaints, resolving issues in a timely manner, and providing valuable product information. By focusing on these aspects of customer service, you’ll be able to develop strong brand loyalty that will serve your business well into the future.

Use data analytics tools

In the world of DTC manufacturing, data is your friend. Using data analytics tools, you can track customer behavior, understand buying trends, and optimize your marketing efforts. Additionally, data analytics can help you improve your manufacturing processes and make better decisions about inventory Management.

If you’re not already using data analytics, now is to start. There are many different software programs available that can help you get started.

By following these seven principles, you’ll be well on your way to success in DTC manufacturing. Keep these tips in mind as you grow your business, and you’ll be sure to find success.