Technology has always been a driving force in the automotive and manufacturing industries. However, the pace of change has accelerated dramatically in recent years, as people are developing and adopting new technologies at an ever-increasing rate. This has a significant impact on how these industries operate, as companies seek to keep up with the latest trends and technologies.

This article will explore the growing demand for new technologies in the automotive and manufacturing industries and how companies respond to this challenge. It will also look at some of the critical technologies driving this change and how they are being used to improve efficiency and productivity in these industries.

1. Electric and autonomous vehicles

As people are becoming more conscious of the environmental impact of their vehicles, there is a growing demand for electric and autonomous vehicles. Electric cars are powered by batteries, which store energy to power the car. On the other hand, autonomous vehicles can drive themselves using various sensors and cameras.

These technologies are already having a significant impact on the automotive industry and are likely to have an even more prominent role in the future. Manufacturers of electric vehicles are investing heavily in research and development to improve the range and efficiency of their products. Autonomous vehicle technology is also being developed rapidly, with several companies working on this technology.

The rise of electric vehicles and autonomous vehicles is forcing companies to invest in new technologies and rethink how they operate. This is because these technologies have the potential to disrupt the traditional business model of the automotive industry.

2. More efficient manufacturing processes

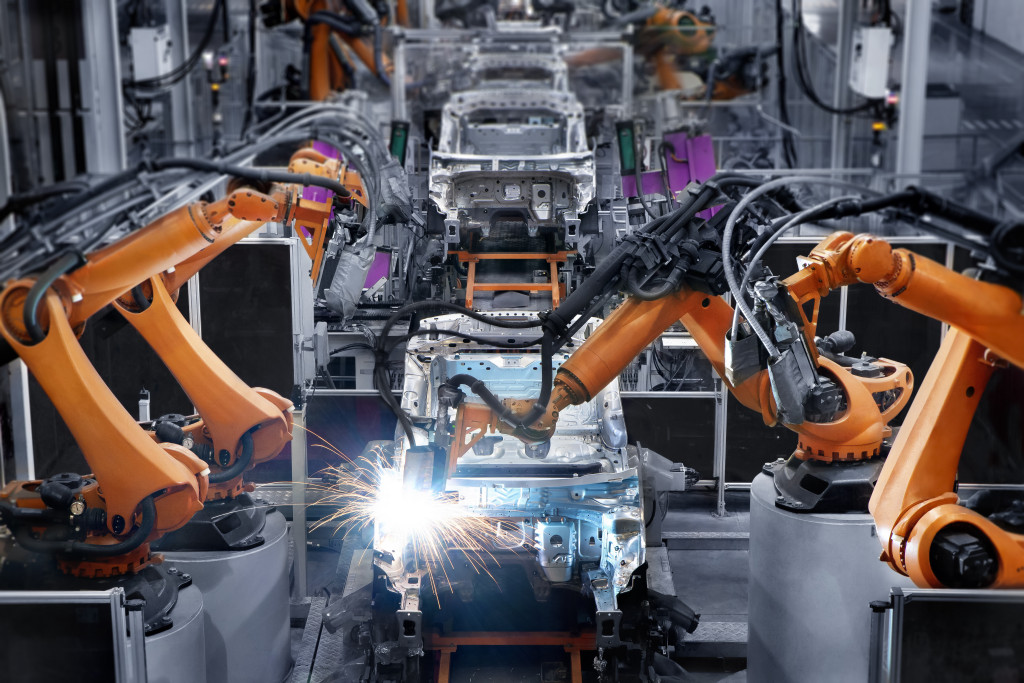

As companies seek to improve efficiency and productivity, they increasingly turn to new technologies to help them achieve this. Manufacturing processes are becoming more automated and efficient as companies adopt new 3D printing and robotics technologies.

3D printing is a process that allows objects to be created from a digital file. This means that products can be designed and manufactured much quicker than traditional methods. Robotics is also being used increasingly in manufacturing as companies seek to automate repetitive tasks.

These sophisticated technologies are used in cleanrooms to ensure that products are clean and free of contaminants before they are shipped out. This is a critical process in the automotive and manufacturing industries, where products must meet strict quality standards. So companies need to work with cleanroom design professionals to ensure that their cleanrooms are up to code.

3. Connected and smart factories

The rise of the Internet of Things (IoT) has significantly impacted the automotive and manufacturing industries. Connected devices are being used to collect data from factories, which manufacturers can use to improve efficiency and productivity.

Smart factories are using this data to become more efficient by reducing waste and improving the quality of products. The use of data analytics is also helping factories to identify problems and improve the way they operate.

Some of the world’s leading companies are investing in smart factories. General Motors, for example, is already on the road to full connectivity, allowing them to collect data from every stage of the manufacturing process. This is a significant investment that will help the company improve efficiency and quality.

4. Improved communication and collaboration

In today’s global economy, companies need to be able to communicate and collaborate. The automotive and manufacturing industries are no exception.

Several technologies are being used to improve communication and collaboration in these industries. These include cloud-based applications, video conferencing, and social media.

Cloud-based applications are becoming increasingly popular in the automotive and manufacturing industries. They allow companies to share data and access it from anywhere globally, especially with the rise of Industry 4.0, which is making factories more connected than ever before.

Some of the world’s leading companies use cloud-based applications to improve communication and collaboration. Airbus, for example, uses a cloud-based system to connect its engineering teams around the world. This allows the company to enhance communication and cooperation among its engineers, essential for designing and building aircraft.

5. Increased focus on sustainability

It is also becoming increasingly important for companies in the automotive and manufacturing industries to focus on sustainability. This is because these industries have a significant impact on the environment.

As the world becomes more aware of the need to protect the environment, companies in the automotive and manufacturing industries are under pressure to reduce their environmental impact.

Renewable energy is one of the key ways these companies seek to become more sustainable. Solar and wind power are being used increasingly to power factories. This is a significant shift, as these industries have traditionally relied heavily on fossil fuels.

The automotive and manufacturing industries are undergoing a significant transformation as companies seek to adopt new technologies and improve efficiency. The five trends discussed above are just some ways these industries are changing. As the world aims to be more connected and sustainable, the automotive and manufacturing industries will need to adapt continuously.